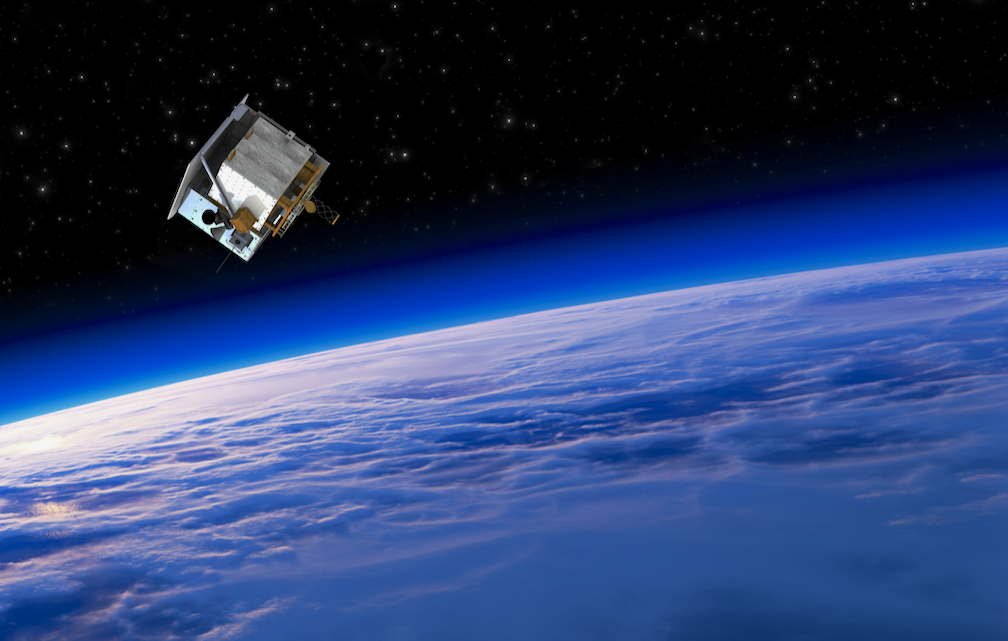

LeoStella, a specialized satellite constellation design and manufacturing company, delivered its first satellite to Loft Orbital Solutions Inc. (Loft Orbital).

LeoStella delivered the “Yet Another Mission-3” (YAM-3) satellite to Cape Canaveral for an upcoming SpaceX launch. The YAM-3 satellite will host a variety of payloads, including a demonstration for the Defense Advanced Research Projects Agency’s (DARPA) Blackjack program and an Internet of Things (IoT) payload for Eutelsat. The satellite is part of a broader contract to build and integrate satellite buses for several upcoming Loft Orbital missions (see information below).

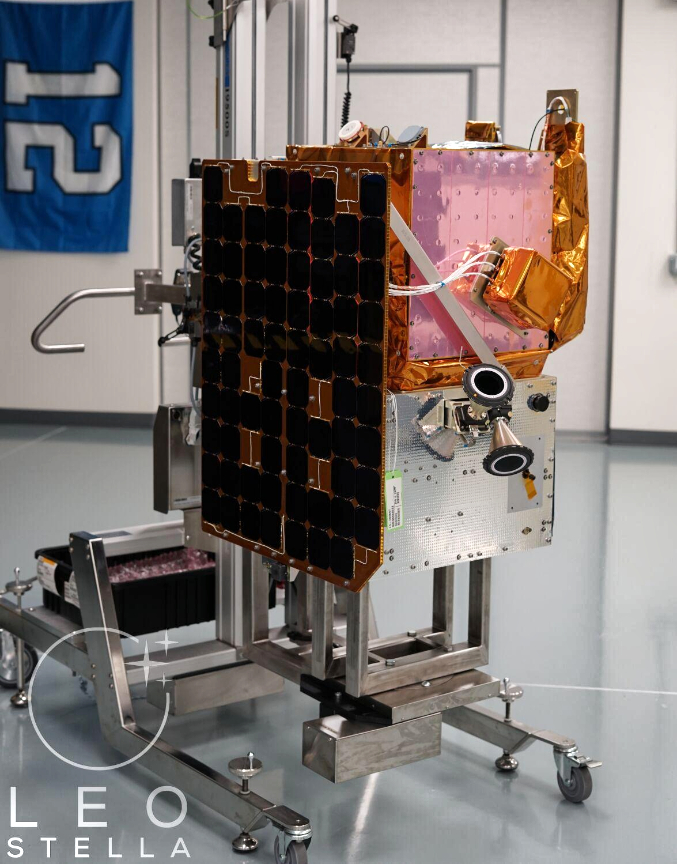

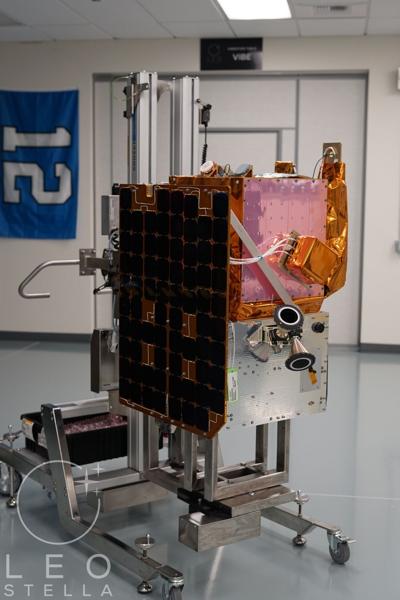

Photo of LeoStella’s YAM-3 smallsat that has been delivered to Cape Canaveral for launch for operator Loft Orbital.

The delivery of this satellite demonstrates LeoStella’s ability to leverage its continuous manufacturing line of commercial satellites to respond to short-term mission needs. LeoStella’s intelligent manufacturing facility uses a software-defined digital process combined with a robust supply chain to make satellite production more flexible and efficient. The factory is designed to maximize efficiency, turning out up to 40 satellites per year, and is scalable to keep pace with the rapidly accelerating market demand.

“We have built a great partnership with Loft Orbital,” said Brian Rider, chief technology officer at LeoStella. “By pulling satellites off our production line, we are able to tailor them for Loft’s Payload Hub and get them delivered in less than half the time normally required for a satellite build cycle. Loft has a unique approach to ‘Make Space Simple’ for their customers. We are proud to be part of their ecosystem of enabling technologies and processes.”

“We’re excited to leverage LeoStella’s manufacturing capabilities to provide our customers with our in-orbit services,” said Pierre-Damien Vaujour, Loft Orbital co-founder and CEO. “We’ve been impressed by the LeoStella team’s agility and dedication, and we’re looking forward to expanding our partnership for future missions. Now that our Payload Hub is fully compatible with LeoStella’s product, our upcoming missions will be even more reliable and delivered to orbit even faster.”

Original information…

Loft Orbital Solutions Inc. (Loft Orbital) has signed a contract with LeoStella to build and integrate satellite buses for several upcoming Loft Orbital missions.

Under the contract, LeoStella will use their state-of-the-art manufacturing facility, which opened in 2019, to produce multiple satellites, based on ESPA-class buses for use in Loft Orbital’s upcoming missions, including its YAM-3 and YAM-5 satellites. YAM stands for “Yet Another Mission.” These buses will be nearly identical in design to the LeoStella satellite bus product line it has developed for other customers.

Loft Orbital flies customer payloads as a service, handling the entire mission on behalf of its customers while ensuring that the customer remains in control of payload operations. Loft Orbital has developed the hardware and software technologies needed to fly multiple payloads on a common bus design without mission-specific customization.

These technologies allow it to procure satellite buses in advance of knowing the payload configuration of the mission, supporting imagers and cameras, radio frequency sensors, scientific payloads for geophysical research or space science, weather and climate sensors, and specialized sensors focused on national security missions. This approach results in a service that provides unparalleled speed to orbit and reliability for Loft customers.

Loft Orbital’s upcoming missions will fly a variety of customer payloads, including a demonstration for the Defense Advanced Research Projects Agency’s (DARPA) Blackjack program, multiple Internet of Things (IoT) payloads for Eutelsat as well as a hyperspectral imager for the United Arab Emirates government. Loft Orbital is currently executing several YAM missions scheduled to launch throughout the next 24 months.

Both LeoStella and Loft Orbital are approaching the increasing industry demand with a similar mindset. LeoStella is leveraging its new facility, outfitted with intelligent workstations, connected tools, and unique automated integration and test approaches combined with a robust supply chain to introduce newfound flexibility and efficiency into satellite production.

Loft Orbital has developed the Payload Hub, a modular, hardware and software payload interface unit that enables it to rideshare any payload configuration on a standard satellite bus. The company has also developed the highly automated Cockpit Mission Control System, which enables customers to task their payload without the burden of conducting mission operations.

Executive Comments

“Loft has developed the hardware and software product stack that enables us to fly a wide range of payloads on a standard bus design,” said Pierre-Damien Vaujour, Co-CEO of Loft Orbital. “Leveraging LeoStella’s existing bus architecture and its flexible production facility provides us with a reliable satellite bus twice as fast as any other vendor. That translates into massive value for our customers in the form of a faster schedule and lower program risk because we procure satellites well in advance of manifesting our missions. We couldn’t be more excited for this partnership.”

“Loft’s innovative approach to payload configuration coupled with LeoStella’s rapid manufacturing of high-quality satellites reduces the barrier of access to space,” said Brian Rider, the CTO at LeoStella. “We are excited about this program with Loft as it demonstrates our ability to minimize the cost and reduce the time required to manufacture satellites. The road to space has never been shorter.”