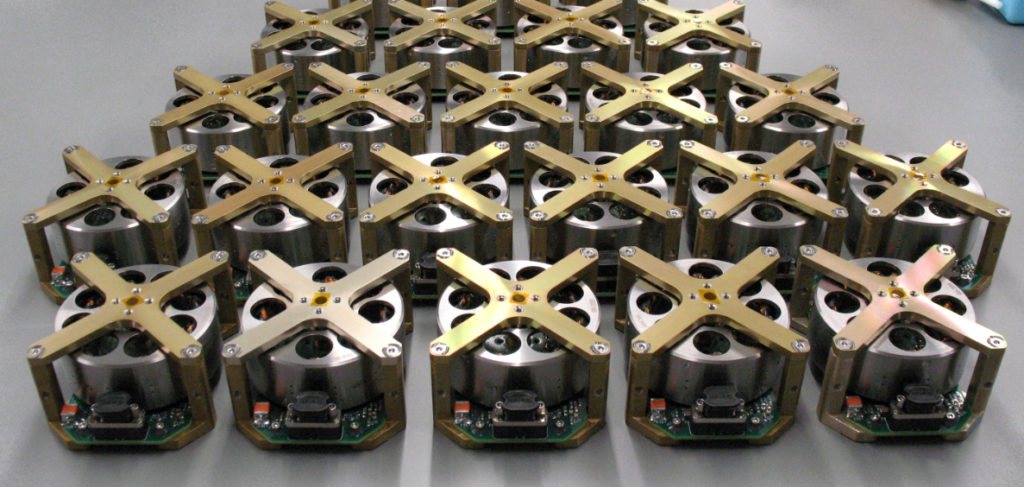

Rocket Lab USA, Inc. (Nasdaq: RKLB) (“Rocket Lab” or the “Company”) is now constructing a new production facility that is capable of supplying as many as 2,000 reaction wheels per year to fulfill the growing demand from satellite constellation customers.

The new production facility, which joins Rocket Lab’s existing 380,000 sq/ft manufacturing footprint, comes as Rocket Lab signs deals to supply reaction wheels for a number of undisclosed satellite constellations. The production line incorporates advanced metal machining centers optimized for unattended operation, automated production tools, and automated environmental testing workstations. More than 16 new roles are expected to support the new production facility and the growing Space Systems operations at Rocket Lab by the end of the year.

The new production facility is the latest expansion of Rocket Lab’s Space Systems business, which was strengthened in 2020 by the acquisition of Toronto-based Sinclair Interplanetary, a provider of high-quality, flight-proven satellite hardware including reaction wheels and star trackers. Sinclair Interplanetary pioneered high-reliability reaction wheels for small satellites and there are close to 200 wheels currently operating on-orbit.

Rocket Lab satellite components, including reaction wheels and star trackers, are now used in more than 200 satellites globally including BlackSky and Kepler Communications constellations. Since acquiring Sinclair Interplanetary, Rocket Lab has added 2,700 sq/ft of production facilities to the Sinclair Interplanetary facilities in Toronto, Canada, and has expanded the team to support higher production volume and enable R&D for new satellite hardware and products.

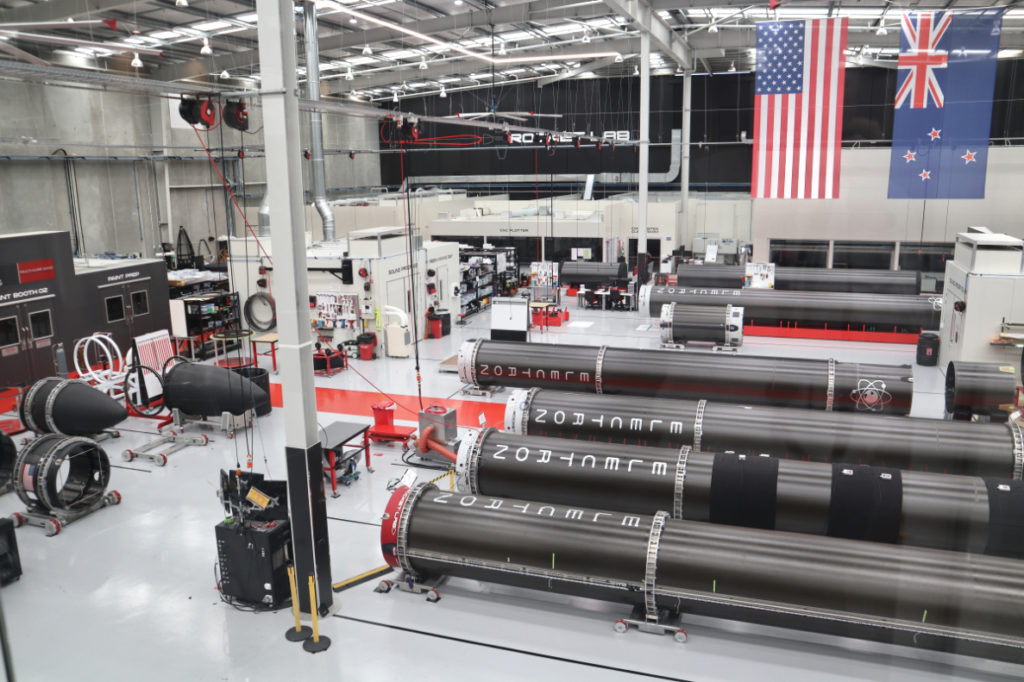

Rocket Lab founder and Chief Executive Officer, Peter Beck, said the new production facility leverages Sinclair Interplanetary’s heritage and marries it with Rocket Lab’s extensive experience with high-rate manufacture of aerospace components for the Electron launch vehicle to make what the Company considers best-in-class satellite hardware available to customers at scale. He said, “For the longest time, spacecraft and satellite components have been built individually by highly specialized engineers with a high price tag and long wait times to match. With the rise in constellations, the demand for high-quality components and spacecraft produced at scale continues to grow and we’re addressing the bottleneck head on. Halfway through 2021, we had already surpassed the total number of satellite components produced by Sinclair annually and we’re continuing to accelerate production to meet the needs of our customers.”