Cosmic Shielding Corporation (Cosmic Shielding), a leading space radiation management company and creator of Plasteel technology, has an agreement with European, in-space, manufacturing tech start-up Space Forge to test Cosmic Shielding’s radiation shielding technology aboard Space Forge’s new small class vehicle.

technology, has an agreement with European, in-space, manufacturing tech start-up Space Forge to test Cosmic Shielding’s radiation shielding technology aboard Space Forge’s new small class vehicle.

The ForgeStar-0 will be launching on Virgin Orbit’s LauncherOne this summer from Spaceport Cornwall.

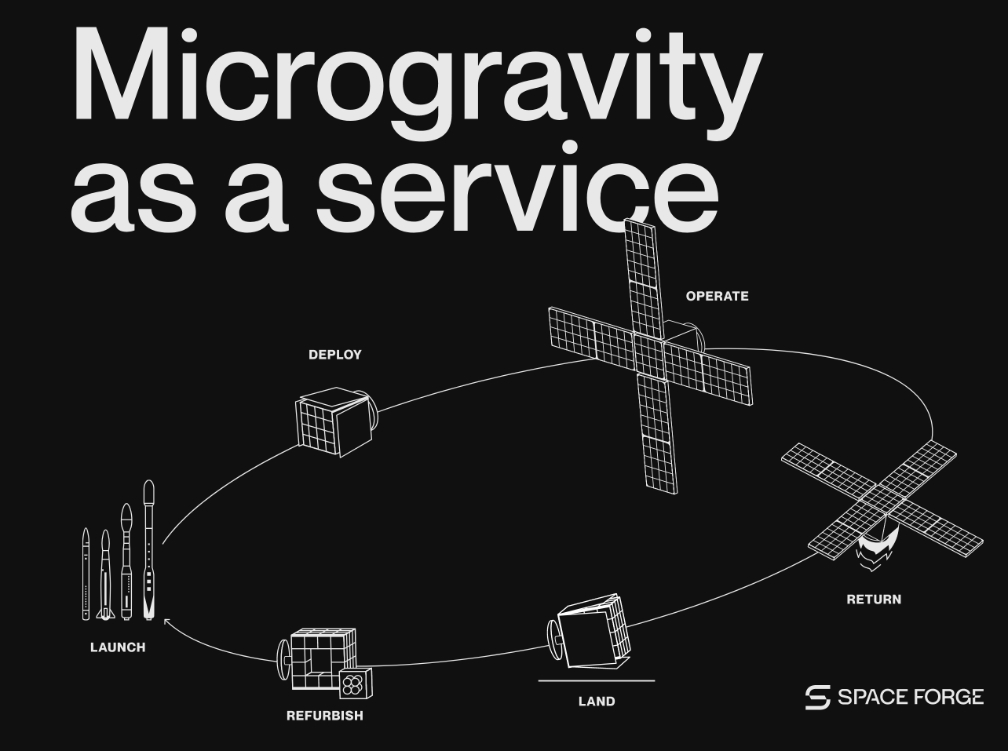

Space Forge recently announced that, along with partners, it is developing a world-first service incorporating launch and return of a new small class of vehicle – the ForgeStar – that can be deployed from conventional launchers to provide rapid, reliable and reusable in-space infrastructure.

This initial mission from Cornwall is an opportunity for Space Forge to test key elements of their return technology and Cosmic Shielding will send a small sample of their revolutionary, patented radiation shielding composite called Plasteel to confirm the survivability of the composite while exposed to the harsh environment of space.

to confirm the survivability of the composite while exposed to the harsh environment of space.

This will be Cosmic Shielding’s first orbital test of the company’s proprietary advanced composite, which is based on materials tested by NASA SRAG. Plasteel has structural properties exceeding traditional alloys used in spacecraft, with shielding properties superior to water and is lighter, cheaper, and easy to manufacture.

A small sample of 3D printed Plasteel composite will be mounted to ForgeStar-0 and exposed to the harsh environment of space. Cameras will be used to monitor the sample and look for any degradation over time with a planned duration of at least nine months in LEO. As part of this mission, Space Forge will also be testing the deployment of their future low cost return technology, ready for a re-entry and landing test on the ForgeStar-1 next year.

“This inaugural mission is a big step forward for us and we are excited that we will not only be trialing our own technology but working with Cosmic Shielding to confirm the survivability of Plasteel in space,” said Andrew Bacon, CTO and Co-founder of Space Forge. “Radiation protection is one of the big challenges for space technology and we are delighted to be using our ForgeStar platforms for research into new solutions.”

in space,” said Andrew Bacon, CTO and Co-founder of Space Forge. “Radiation protection is one of the big challenges for space technology and we are delighted to be using our ForgeStar platforms for research into new solutions.”

“We’re thrilled to have Cosmic Shielding on our first mission,” said Joshua Western, CEO and Co-founder of Space Forge. “Their mission to increase the longevity of space systems with this revolutionary technology mirrors our drive to both increase access to space alongside return and reuse of spacecraft. We look forward to continuing to collaborate with innovative companies like Cosmic Shielding who are at the forefront of the industry.”

“Our ultimate goal is to make the space industry more sustainable, cost effective, and safer, which is why we say we are working to build a better frontier,” said Yanni Barghouty, co-founder and CEO of Cosmic Shielding. “If we are going to be successful with in-space manufacturing in the future, streamlined logistics are imperative. Having a single, multifunctional composite, like Plasteel, makes building in space or extreme environments much simpler, cheaper, and safer. We are very confident that the Plasteel sample will perform well in this initial test with Space Forge and are eager to see the technology in space, which is a very important step in our continued growth towards building entire space structures, like factories in space, from this composite in the future.”

Cosmic Shielding plans to modernize the way spacecraft are manufactured by making them safer, cheaper, faster, and less complex to build. When integrated in spacecraft, Plasteel provides complete micrometeoroids and orbital debris protection and protection from radiation for sensitive components and people. Furthermore, combining the material cost savings and 3D printed manufacturing process, Cosmic Shielding’s Plasteel spacecraft will be manufactured and delivered in approximately one week following order, cost up to 50 percent less than traditional aluminum satellite structures, and offer tremendous environmental benefits.

“Having a long-term reduction of waste in orbit is not possible without proper shielding,” added Barghouty. “Manufacturing spacecraft from safer, stronger materials in combination with advancements in on-orbit servicing technology will help us move away from the idea that satellites are disposable, creating a more sustainable space ecosystem.”

This mission is an example of the collaborative relationship between growing commercial space companies in the US and UK. It is also an historic moment for UK space, as the ForgeStar-0 is the first satellite to be built in Wales and will also be launched from the country’s first, domestic spaceport; Spaceport Cornwall in Newquay.

Cosmic Shielding Corporation (Cosmic Shielding) is the leading space radiation management company and creator of the world’s first multifunctional shielding polymer (MSP) Plasteel technology designed to radically extend spacecraft operational life, reduce operational costs, and protect people in space. Founded by world leading scientists from NASA and ESA, with 90 years of combined experience tackling the challenges of space radiation, Cosmic Shielding aims to build a future where humans can live and work as safely in space, as we do on Earth today.

Space Forge Ltd is a UK start-up on a mission to lead the clean industrial revolution by harnessing space. The company is developing fully returnable satellites that are designed for manufacturing next generation super materials in-space. In creating a reliable return, Space Forge will advance the expansion of the microgravity market for premium research and development applications by lowering the barriers to entry. The company is focused on R&D initiatives where dedicated return from the space environment can add a significant benefit, or overcome obstacles found terrestrially, to unlock new value and innovation.