Fleet Space has unveiled their new 3D printer at the firm’s expanded manufacturing facility in Adelaide, Australia. This location was initially used to print radio frequency (RF) patch antennas and other equipment and is now capable of working in metals that include aluminum and titanium.

The new technology represents a significant boost to Fleet Space’s capabilities, enabling the development and manufacture of new products in-house and paves the way for the company’s fully 3D-printed, Alpha satellite.

The 3D printer will initially be used to produce the S-Band Antenna RF Patches already in use in the company’s existing satellite constellations. These antennas receive and transmit signals between the constellations in LEO as well as portals and modems on the ground. In future, engineers will use it to produce structural parts for its new-generation Alpha satellite to optimize weight and increase vertical integration.

By reducing turnaround times and enabling low-risk prototyping, the 3D printer enables more efficient R&D in areas such as filters and other passive RF components. Supplied by Konica Minolta, the new machine uses direct metal printing (DMP) technology, in which a laser welds thin layers of metal powder to produce highly complex metal parts. DMP provides unlimited design flexibility and overcomes many of the geometry and surface retention limitations imposed by traditional manufacturing techniques.

The 3D printer is the centerpiece of Fleet Space’s newly extended manufacturing facility in Adelaide, South Australia, which now employs more than 80 staff in order to support the company’s increased precision manufacturing capacity and future bespoke projects

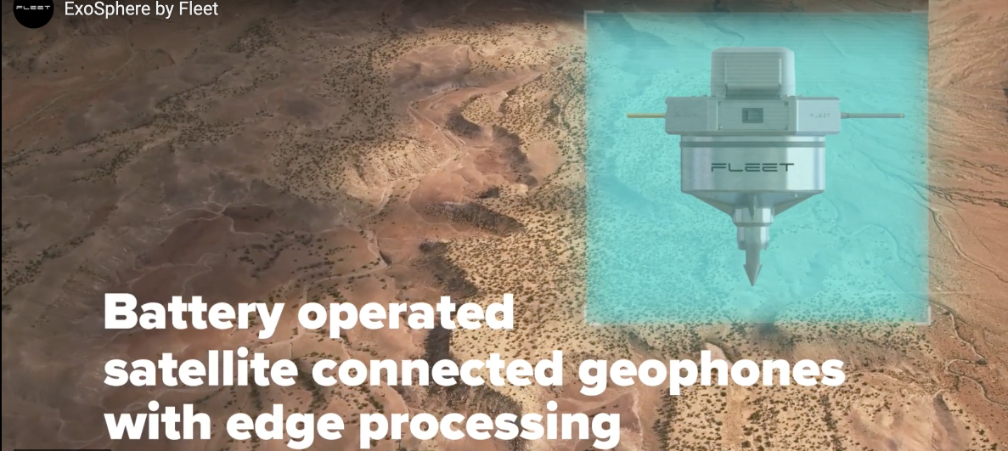

Fleet’s latest technology, ExoSphere, has just reported successful results from trials at Australia’s newest Lithium miner Core Lithium’s Finniss Project in the Northern Territory. ExoSphere provides a solution for the exploration industry delivering lightning fast, highly scalable 3D mapping solutions to pinpoint minerals and increase accuracy in drilling targets.

Fleet’s Geodes (that are planted in the ground acting as a geophone sensor), from ExoSphere, are connected to Fleet’s satellites where the RF patch antennas are used. This technology is being rolled out globally through collaboration with the world’s largest and most progressive explorers and is supporting the global effort to find more than $13 trillion (as defined by the International Monetary Fund) value in these rare Earth materials to support global, sustainability goals.

Flavia Tata Nardini, CEO and Founder, Fleet Space Technologies, said, “Bringing our 3D printing capability entirely in-house rather than outsourcing it offers huge benefits to us and our customers. As well as enabling us to make complex components for our current models and future Alpha satellites, it increases efficiency from design to production, making the whole process more cost-effective; and by being fully autonomous, we can eliminate delays in shipping and sourcing. We’re capitalizing on our existing knowledge and experience of 3D printing antennas and structural components.”

Flavia continued, “And this is just the starting point. As our engineers explore and understand the full potential of 3D printing, we’ll be able to use it to develop new designs and produce circuit boards and other electrical components. It’s also another significant step towards our goal of producing a fully 3D printed Alpha satellite. The 3D printer is bringing us a step closer to mass production of our 288 satellite constellation where we estimate to produce 4-8 satellites every month. The new metal 3D printer, and the expansion of our Adelaide facility, underlines our commitment to domestic manufacturing. This is also reflected in our huge increase in staff numbers, from 34 in May 2021 to more than 80 today, almost tripling in size. We’re a confident, growing business with our eyes firmly on the future.”

Fleet Space is built from a culture of innovation, executed in collaboration with South Australia’s ecosystem of leading space technology and advanced engineering companies. From its base in Adelaide, Fleet has pioneered the use of additive manufacturing (3D printing) to drive cost and production efficiencies in the manufacture of satellites. This includes Fleet’s forthcoming planned constellation of 288 smallsats, including Alpha, which will integrate the company’s advanced beamforming technology and patented antennas to unlock greater connectivity more quickly and in more locations. In December of 2021, Fleet also announced its commitment to establishing a hyper factory in Adelaide’s landmark ‘Australian Space Park’ development. This is with the support of the South Australian Government which committed AUS$20 million to Australia’s first dedicated space manufacturing hub. The AUS$66 million Australian Space Park, in which Fleet Space Technology will build their Hyper Factory, will be the first of its kind in the southern hemisphere.