Phase Four is going to expand their Maxwell, turn-key, plasma propulsion line and offer satellite manufacturers an industry-first, high performance engine using an inexpensive, domestically sourced, iodine-based propellant — Max-V leverages the Maxwell Block 2 engine’s innovative architecture and builds on the radio-frequency thruster’s propellant agnostic capabilities.

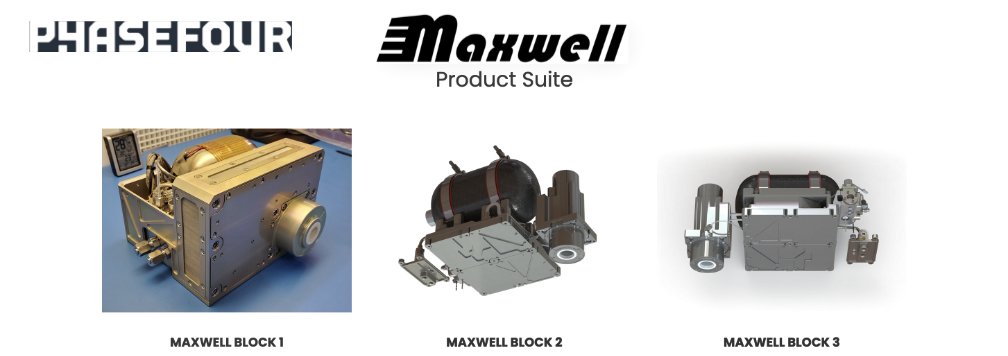

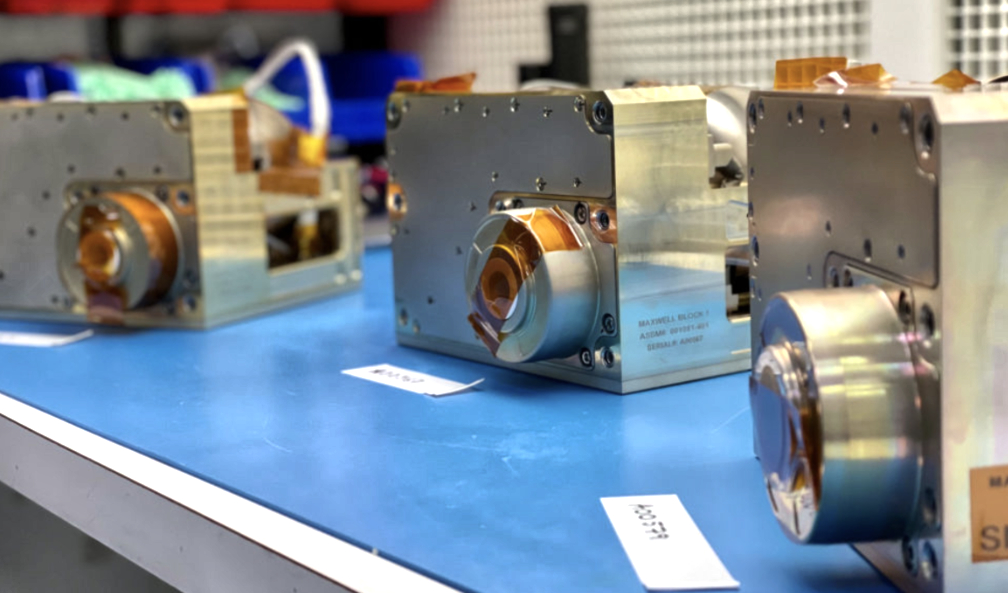

Phase Four’s Maxwell Block 1 engine gained flight heritage in early 2021. Maxwell Block 2 engine deliveries began earlier this year. With double digit commercial flight units delivered, the company is now focusing on its Max-V development effort.

Maxwell’s new, chassis-style, design enables rapid on-ramping of improvements in the core areas of the thruster, power electronics and propellant subsystems. This architecture is streamlining the Max-V development process as is the company’s significant experience with iodine-based propellants through its recent U.S. Air Force AFWERX award.

Max-V is anticipated to be available for order in the second half of 2023. The system is designed to operate from 200 Watts to 1.5 kiloWatts, and achieve 50 mN thrust, over 1,200 s Isp and deliver over 100 kNs total impulse. Max-V’s iodine-based propellant will cost under $400 per kilogram and be incorporated in the purchase price. Max-V’s form factor is similar to Phase Four’s current Maxwell Block 2 engine. The system will ship fully fueled, ready for installation and will require no ground fueling operations prior to launch.

“Legacy electric propulsion systems are tied to noble gases like xenon and krypton,” said Phase Four CEO, Beau Jarvis. “These noble gases, while high performing, are largely sourced outside of the United States in China, Russia and Ukraine. The US has no real control over this supply chain, which is subject to high price volatility and recent severe supply issues. We’ve always said that Phase Four delivers game changing propulsion systems, and Max-V will do just that. We are building a product that will dramatically lower costs and extend operational lifetimes of small satellites in low Earth orbit and provide significantly higher total impulse for missions beyond LEO.

Phase Four board member, former NASA Administrator Jim Bridenstine said, “This year we’ve seen xenon prices spike to over $30,000 per kilogram. This is cost prohibitive for both commercial and government satellite constellations in low Earth orbit. The US is the world’s third largest iodine producer, and my home state of Oklahoma leads the way in domestic production. With Max-V, we can ensure a fully domestic supply chain and readily accessible low cost propellant.”

“Maxwell’s new modular chassis architecture enables us to introduce improved capabilities within the same form factor,” said Phase Four CTO, Umair Siddiqui. “Using an iodine-based propellant instead of a noble gas propellant stored at very high pressure provides a number of benefits to our customers. Iodine stores as a solid without high pressure valves or vessels, which means we can deliver fully fueled engines directly to our customers.” Siddiqui continued, “Iodine also stores about three times more densely than xenon, which means our propulsion systems will offer much higher total impulse in the same unit volume as legacy electric propulsion systems.”

Phase Four is a disruptive provider of next generation electric propulsion (EP) solutions for small satellites. The company was founded in 2015 to address the demands of the rapid proliferation of satellite constellations and to accelerate the advancement of its radio-frequency thruster (RFT). The Phase Four RFT represents a revolutionary new architecture that realizes lower cost, mass-manufacturability, miniaturized power electronics, and propellant agnosticism over incumbent technologies, without compromising performance. In 2021 Phase Four’s Maxwell turn-key propulsion system achieved flight heritage and is now being regularly utilized by small satellite operators. Learn more at www.phasefour.io.