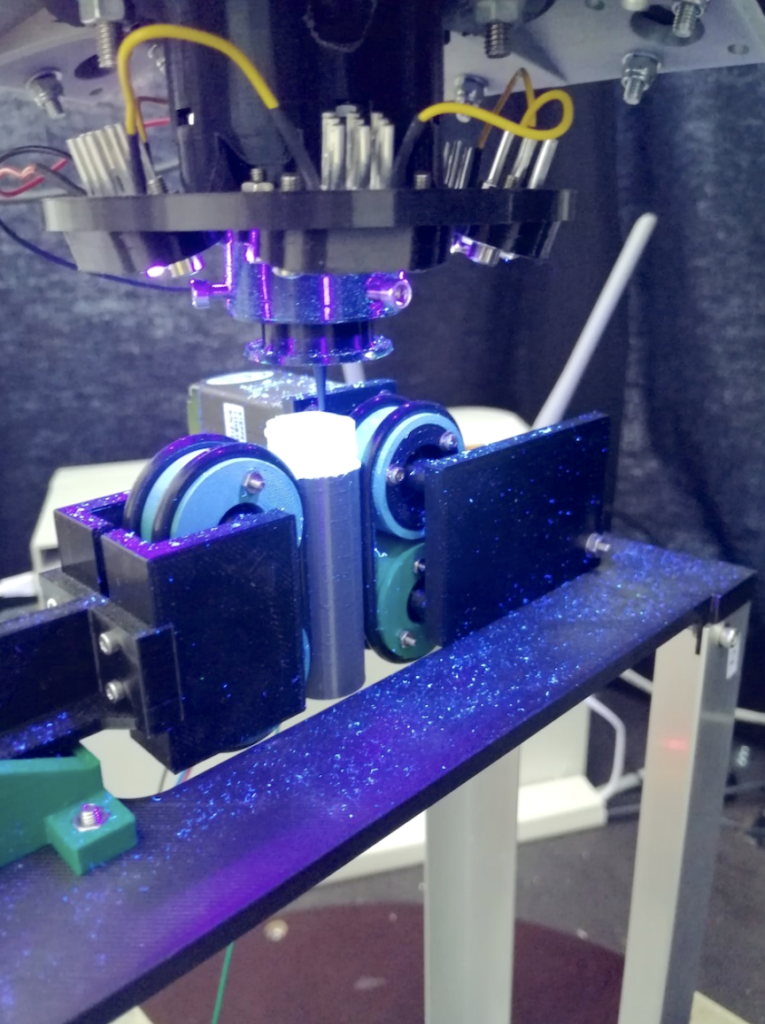

DCUBED, the German NewSpace hardware manufacturer, announced it will demonstrate in-space manufacturing as part of a demonstration mission expected in Q1 2024. This will be the first time ever that a product has been manufactured in free space.

The demonstration will see the production of a roughly 30 centimeter high, 3D printed truss structure, and is designed to prove the efficacy of in-space manufacturing and highlight the game-changing potential that such capabilities promise to deliver for production in-orbit.

“Payload limitations and costs are real barriers hindering the use of space for the benefit of mankind. There is an urgent need for large structures in orbit to support an ecosystem providing services as diverse as internet from space, IoT, and Earth observation. The establishment of our new key business division shows that we at DCUBED always want to push the boundaries of what is possible, enabling our partners and customers to think big in space. Our demonstration of manufacturing in free space promises to revolutionize in-space fabrication and repair of space structures and trigger a paradigm shift in how we approach the production of space hardware, opening many doors which we can’t even imagine right now. This is a truly disruptive enabling technology.” Dr. Thomas Sinn, CEO & Founder, DCUBED.

The upcoming demonstration is a major milestone in DCUBED’s efforts towards establishing in-space manufacturing capabilities for larger space structures, especially for SmallSat applications, due to be demonstrated by the company in the next couple of years. This program includes an in-orbit experiment of truss-structure manufacturing in 2025 and an in-orbit mission demonstration, in 2026, for a multiple kilowatt (KW) SmallSat solar arrays.

A space mechanism builder with 15 products already in orbit, DCUBED, which is headquartered outside Munich, Germany, is establishing an office in Broomfield, Colorado, an ideal location within the key United States space market.