Benchmark Space Systems has revealed the firm’s Xantus electric propulsion system has successfully deployed and will undergo subsystem health check and operational verification, including a range of firing modes, aboard mission prime Orion Space Solutions’ 12U cubesat in LEO.

electric propulsion system has successfully deployed and will undergo subsystem health check and operational verification, including a range of firing modes, aboard mission prime Orion Space Solutions’ 12U cubesat in LEO.

Benchmark’s first electric propulsion system in space, launched aboard the SpaceX Transporter-10 rideshare mission, is tasked with end-to-end mission operations for Orion Space Solutions’ satellite as it supports the demonstration of cloud and weather data mapping for potential, future, military operations. Once the mission objectives are met, the Xantus metal plasma thrusters will be used to deorbit the spacecraft, a critical capability for regulatory compliance and the sustainability of LEO infrastructure.

Based on the early mission milestone, Benchmark is greenlighting shipments of dozens of Xantus MPTs to meet the pent-up demand for proven electric and hybrid propulsion systems among commercial and government operations. Of the 50-plus Xantus EP thrusters being shipped this year, Orion has baselined units in upcoming missions — at least ten will go to UK-based In-Space Missions, a wholly owned subsidiary of BAE Systems plc, among several, smallsat builders and operators that are integrating Xantus MPTs into electric and hybrid propulsion configurations for upcoming missions.

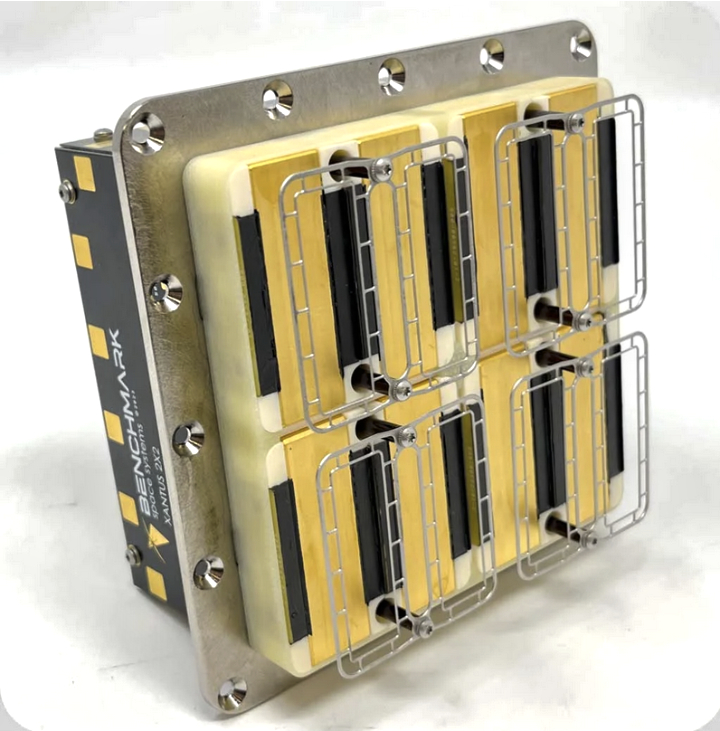

Multiple satellite and mission operators that need to go fast, station keep, and make precision maneuvers in space, are evaluating Benchmark’s hybrid duo of Xantus EP thrusters and Halcyon non-toxic chemical propulsion systems, which unlock expanded dynamic operations for 12U to ~200kg spacecraft that are often limited by a single technology, compromising mission capability and value.

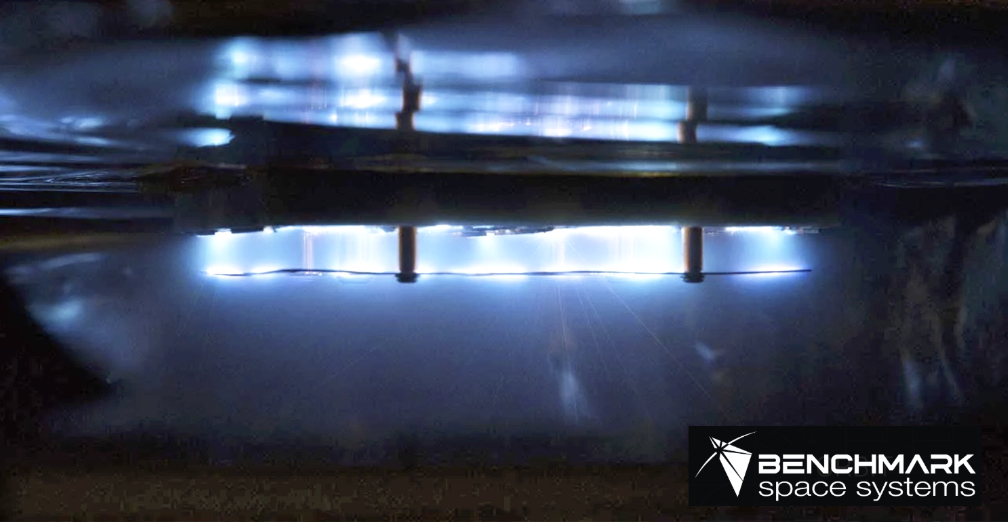

The production Xantus metal plasma thrusters are baselined to run on the metal molybdenum, which offers the best combination of properties and efficient thrust generation among a variety of metal propellants tested in trials (also copper, stainless steel, aluminum, and magnesium). The MPTs are designed to ultimately run on metals that can be harvested in space, including spent space vehicle materials and orbital debris.

Early operations and telemetry will be used to validate the Xantus EP system’s thrust across several power levels and other key capabilities, which boost mission readiness and assurance levels realized during third-party testing at NASA’s Glenn Research Center in Ohio and at Benchmark’s Research and Development facility in Pleasanton, California.

The milestone debut of Benchmark’s electric propulsion system in space comes less than 18 months after the company acquired the metal plasma thruster technology from Alameda Applied Sciences Corporation and follows a previous mission launch in January 2023 that did not deploy.

The Xantus electric propulsion system, with its innovative MPTs, is one key element of Benchmark’s full in-space mobility strategy and market-leading lineup of propulsion systems and solutions. The company offers electric, green chemical, and hybrid platforms designed to provide speed, endurance, precision maneuvering, and deorbit capabilities to meet the fast-growing demand for dynamic and sustainable space operations across multiple orbits and mission profiles

“The Benchmark team is thrilled that our Xantus electric propulsion system and metal plasma thrusters are supporting this important mission for Orion Space and the US Government,” said Chris Carella, Chief Commercial Officer for Benchmark Space Systems. “Our government and commercial mission partners around the world have closely followed this historic first, as our Xantus metal plasma thrusters demonstrate their capabilities in space. Our partners have been preparing for space with our software and engineering development units (SDUs/EDUs), and they’re excited to soon be receiving shipments of flight units to close on their own missions in the months ahead.”

“Our Xantus MPTs are designed to provide optimal station keeping for most cubesats, microsats in the range of 5 to 250 kilograms, and precision operations for ESPA-class satellites from 250 to 1000 kilograms. That’s a wide sweet spot, and we look forward to enabling dozens of upcoming missions to fly using what promises to be an extremely valuable electric propulsion tool in LEO, MEO, and GEO,” said Kent Frankovich, Benchmark’s Vice President of Electric Propulsion, who is leading the company’s metal plasma thruster development.