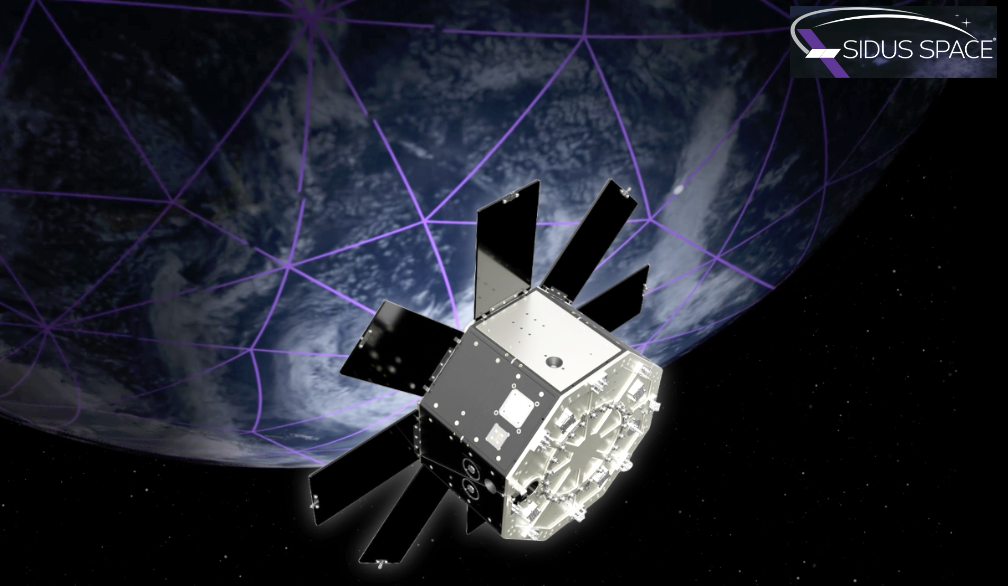

Sidus Space, Inc. (NASDAQ: SIDU) has established two-way communications with its state-of-the-art, 3D-printed satellite, LizzieSat , focused on Earth Observation (EO) and remote sensing solutions powered by Geospatial Artificial Intelligence (Geo-AI).

, focused on Earth Observation (EO) and remote sensing solutions powered by Geospatial Artificial Intelligence (Geo-AI).

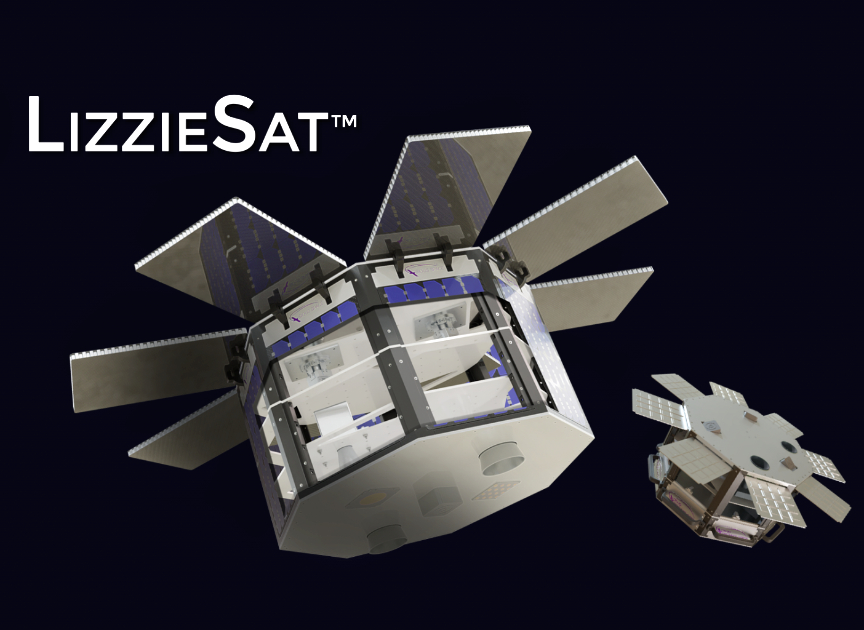

Using a state-of-the-art production process, the Sidus Space LizzieSat uses Markforged’s flame-retardant Onyx FR-A material to produce the bus structure with metal-like strength, while also reducing cost, weight, and production time. Once full production cadence is achieved, the expected time to manufacture the satellites is 45 days and that includes printing and assembly. Following on the successful launch and deployment of its first LizzieSat earlier this year, Sidus has two additional LizzieSats manifested for launch before the end of the year.

Capable of integrating multiple sensors, LizzieSat facilitates simultaneous data collection to support agriculture, maritime, oil and gas and other industries. These sensors and receivers include hyperspectral, multispectral, automatic identification system (AIS), and optical technologies. Additionally, the satellite features Sidus’ onboard FeatherEdge AI hardware and software solution for near real-time, actionable intelligence processing of imagery and sensor data.

“Sidus’ cutting edge, state-of-the-art LizzieSats are at the core of our high-margin Data-as-a-Service business model,” said Carol Craig, Sidus’ CEO and Founder. “The combination of our rapid, 3D-printing production process, our multi-sensor coincident data collection, and the integration of on-orbit AI gives Sidus an edge as we build our satellite constellation to collect and sell data to our customers.”