Web Industries Inc. will highlight their capability to design and manufacture thermal insulation blankets and micrometeoroid shielding products at the Small Satellite Conference 2020, August 3-6. Normally held at Utah State University, Logan, Utah, this year’s SmallSat will take place entirely online, due to the coronavirus pandemic.

Space and aerospace OEMs and other visitors registered for SmallSat are invited to meet online with Web Industries officials at one of four designated time slots during the conference. All meetings are individual and confidential. Web engineers will be on hand to meet at the following times: 1:00 to 2:00 p.m. Eastern Standard Time, Monday, Aug. 3, through Thursday, August 6.

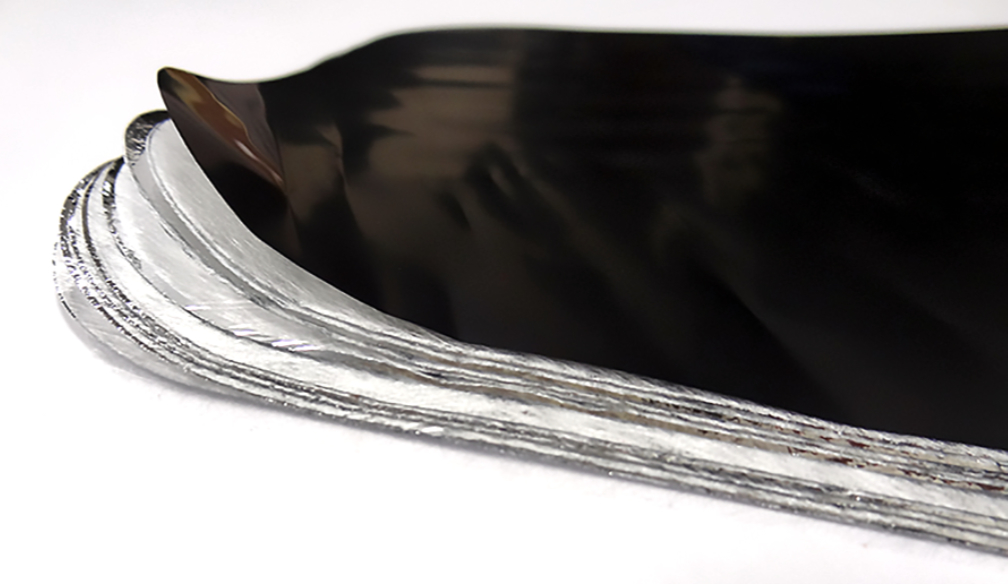

At SmallSat, Web Industries will showcase its multi-layer insulation (MLI) blankets and formatted materials for thermal management tasks aboard satellites and space vehicles. MLI blankets are lightweight components consisting of multiple layers of film or foil that reflect radiated heat energy, offering exceptional performance in space environments.

In a new development, Web is employing Creo CAD software for the first time in the firm’s design of MLI blankets. The software enhances Web’s ability to process three-dimensional images and convert them into two-dimensional shapes, resulting in MLI blankets that more closely conform with dimensional requirements.

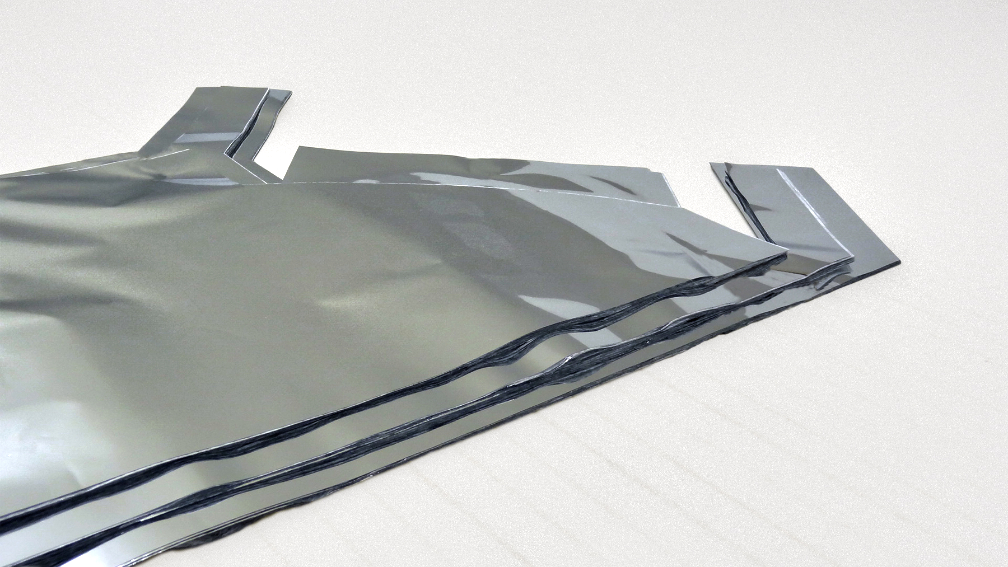

In addition, Web will exhibit its proven capability to design and manufacture micrometeoroid and orbital debris (MMOD) shielding products. High-velocity MMOD particles pose a serious risk of damage to satellites and space vehicles, especially in low Earth orbits. MMOD shields consist of multiple layers of Kevlar® and other high-strength materials. Successive shield layers break up MMOD particles on contact and prevent debris from damaging the spacecraft.

Executive Comment

“During SmallSat, Web representatives plan to address certain key issues of interest to space/satellite OEMs as part of the virtual meeting framework,” said Web’s Business Development Manager for Thermal Insulation, Lee Smith. “These include efforts to speed turnaround and reduce cycle times in MLI blanket production, the benefits of increasingly automated MLI manufacturing, and the ability to supply finished blankets with integrated fasteners directly to the launch pad.”