Relativity Space, the first company to 3D print an entire rocket and build the largest metal 3D printers in the world, has closed a $650 million Series E equity funding round.

The round was led by Fidelity Management & Research Company LLC with participation from investors including Baillie Gifford, funds and accounts managed by BlackRock, Centricus, Coatue, K5 Global, Soroban Capital, Tiger Global, Tribe Capital, XN, Brad Buss, Mark Cuban, Jared Leto, and Spencer Rascoff, among others. Following the announcement of its fully reusable, entirely 3D printed rocket, Terran R, the company’s latest round of funding enables the scaling of the Terran R program and long-term infrastructure development.

As a two-stage, 216-foot-tall rocket with a 16 foot diameter, and a 5 meter payload fairing, Terran R will be entirely reusable and capable of launching 20,000 kg to LEO, starting in 2024 at the company’s launch site at Cape Canaveral. Created in Relativity’s Factory of the Future, by the same printers and the same team as Terran 1, Terran R has unique aeronautical features, complex structures, and has the ability to launch 20X more payload than Terran 1.

Terran R will be outfitted with seven, 3D-printed, Aeon R rocket engines capable of 302,000 lb. thrust each, while its upper stage houses one Aeon 1 vac engine. Terran R also represents a large leap towards Relativity’s mission to build humanity’s multi-planetary future, eventually offering customers a point-to-point space freighter capable of missions between Earth, Moon and Mars.

Within the last six months, the company has continued to execute on commercial and technical milestones, including signing its first anchor customer for Terran R, the company’s fully reusable, entirely 3D-printed launch vehicle. Relativity has now completed printing of over 85% of the first Terran 1 orbital rocket, including its first and second stage, keeping momentum for its launch end of this year from Cape Canaveral.

Terran 1 continues to garner commercial traction, including recently announced customer contract with TriSept, its first launch contract with the U.S. Department of Defense, and a Venture Class Launch Services Demonstration 2 (VCLS Demo 2) contract with NASA. Over the last year, despite COVID-19’s impact on the overall economy, Relativity has accelerated its pace of hiring, now at 400+ employees with plans to hire an additional 200 team members this year.

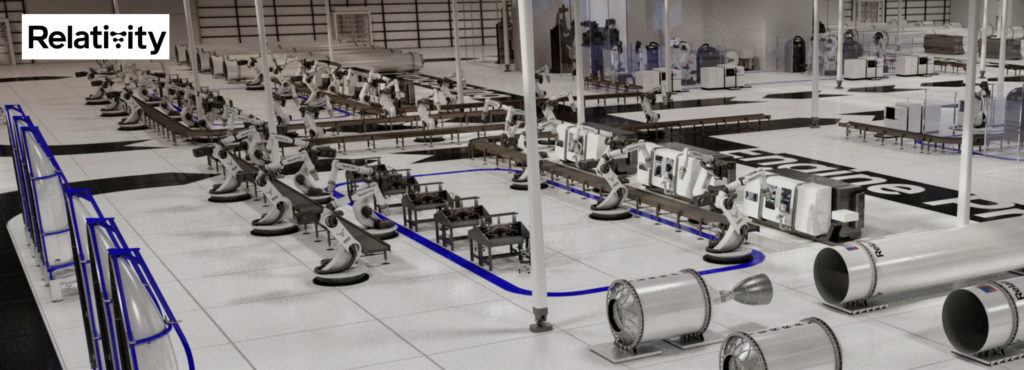

Relativity’s simplified supply chain enables the company to build its rockets, including the world’s first entirely 3D printed rocket Terran 1 and its fully reusable, entirely 3D-printed rocket, Terran R, with 100x fewer parts in less than 60 days. By fusing 3D printing, artificial intelligence, proprietary software, and autonomous robotics, Relativity has created an entirely new value chain for aerospace, starting with orbital launch.

With 3D printing production, Relativity has created a new tech stack for aerospace that uses software-driven manufacturing, exotic materials and unique design geometries that are not possible in traditional manufacturing, driving unprecedented innovation and disruption in the industry. With continued high demand for Terran 1, Relativity has secured nine launch contracts from both private and government customers, and with satellite constellations representing the largest part of the growing market, Terran R helps the company serve its growing pipeline of commercial interest.

“From our founding days in Y Combinator just five years ago, we planned on 3D printing Terran 1 and then Terran R – a 20X larger fully reusable rocket – on our Factory of the Future platform,” said Tim Ellis, CEO and co-founder of Relativity. “Today we are one step closer to this goal. Together with our first rocket Terran 1, our second product, Terran R, will continue to take advantage of Relativity’s disruptive approach to 3D printing – reduced part count, improved speed of innovation, flexibility, and reliability – to bring to market the next generation of launch vehicles. Relativity was founded with the mission to 3D print entire rockets and build humanity’s industrial base on Mars. We were inspired to make this vision a reality, and believe there needs to be dozens to hundreds of companies working to build humanity’s multi-planetary future on Mars. Scalable, autonomous 3D printing is inevitably required to thrive on Mars, and Terran R is the second product step in a long-term journey Relativity is planning ahead.”